Our Unit Converter

The ESI Unit converter allows you to quickly and easily access a conversion tool to work out your preferred unit of pressure measurement wherever you may be. Whether out on-site or in the office.

Download the ESI-USB© Software

The ESI-USB© software allows you to connect your ESI transducer to your laptop or PC and be up and running monitoring pressure data within ten minutes. The software auto-updates and is compatible with Windows 8, 10 & 11.

Custom Designs for Subsea Pressure Transmitters

Many of the customised designs are based on standard products with modifications to allow operation in underwater environments; seals, welded housings conforming to NACE corrosion resistance requirements and subsea connector assemblies ensure high integrity even at extreme depths. ESI’s team of qualified engineers have extensive experience in electronic, software and mechanical instrumentation, and by working closely with customers, are able to create unique solutions meeting all of the specifications required.

At the heart of each design is the unique Silicon-on-Sapphire sensor technology; a sensor not only with high sensitivity and stability but also rugged and resilient to high overload pressures and transients. The silicon is grown into the surface of the sapphire, resulting in incredible durability and stability with virtually no hysteresis and outstanding insulation properties, allowing the sensor to operate over a very wide temperature range. The excellent elasticity of the sapphire ensures high repeatability over a long service life.

ESS & Hyperbaric Testing

Pre-conditioning and testing is fundamental to the success of any subsea transmitter. ESI has made significant investment in test facilities, meaning that each unit will be environmentally screened and subjected to 3300 metres of submersion before leaving the factory, confirming at least 20 years of reliable service on the seabed with no concern about leakage or integrity.

Documentation & Certification

Document packages are required more frequently and are quickly becoming standard requirement within the oil, gas and subsea market. Therefore each ESI product is supplied with a complete package of documentation confirming calibration, accuracy, material conformity, hyperbaric test and ESS test certificates.

Meet the products…

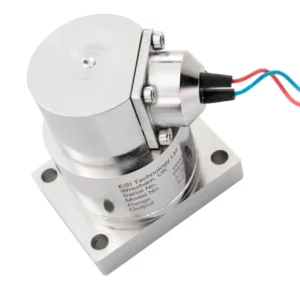

PR3913 and PR3915 Series

Housed in fully welded body with Inconel 625 wetted parts, this series is intended for permanent immersion in pressurised dielectic oil and protected from ingress with a high pressure glass-to-metal lead-through. The product can withstand external pressure up to 3,000 metres water depth and provides secondary pressure containment up to 1,650 bar. The PR3915 has two silicon-on-sapphire pressure sensors and electronics for reliable dual redundancy.

PR3914 Series

This design is intended for permanent immersion with external pressures of up to 6,000 metres water depth, with secondary pressure containment up to 1,650 bar. Units can be supplied with hyperbaric test certificates to 3,000 metres water submersion. A range of specialist subsea connections are available.

PR3920 Series

The PR3920 subsea differential pressure was developed to offer high accuracy differential pressure measurement on chemical injection valves. Typically, differential pressures of 50 bar can be monitored with a high accuracy. The Silicon-on-Sapphire sensor permits high line pressures of up to 1000 bar to be applied independently to either of the two pressure ports without affecting the performance of the transmitter.

Contact the sales team for more information or view our range of oil, gas and subsea products here http://www.esi-tec.com/oil-gas-subsea-pressure-transmitter