Our Unit Converter

The ESI Unit converter allows you to quickly and easily access a conversion tool to work out your preferred unit of pressure measurement wherever you may be. Whether out on-site or in the office.

Download the ESI-USB© Software

The ESI-USB© software allows you to connect your ESI transducer to your laptop or PC and be up and running monitoring pressure data within ten minutes. The software auto-updates and is compatible with Windows 8, 10 & 11.

What is a Pressure Transmitter?

What is a Pressure Transmitter?

A pressure transmitter is a device that converts pressure measurements from liquids, gases, or steam into an electrical signal for monitoring, control, or recording purposes. These instruments are essential in various industries, including manufacturing, oil and gas, hydrogen, chemical processing, and HVAC systems, where accurate pressure monitoring is crucial for safety, efficiency, and performance.

How Pressure Transmitters Work

How Pressure Transmitters Work

Pressure transmitters operate by sensing the pressure exerted on a diaphragm or sensor, which deforms in response to the applied pressure. This deformation is converted into an electrical signal, typically using a sensor like a strain gauge or silicon-on-sapphire. The signal is then processed and transformed into a readable output that can be displayed or integrated into control systems. Outputs can range from analogue signals (e.g., 4-20 mA) to digital signals, depending on the system’s requirements.

Types of Pressure Transmitters

There are many different types of pressure transmitters, each designed for specific applications. The most popular types include:

Absolute Pressure Transmitters: These measure pressure relative to a perfect vacuum (zero reference point). They are used in applications where accurate vacuum measurement is essential, such as in scientific research or the aerospace industry.

Gauge Pressure Transmitters: These measure pressure relative to ambient atmospheric pressure. They are commonly used in applications where internal system pressure needs comparison with the external environment, such as fluid tanks or open-air systems.

Differential Pressure Transmitters: These devices measure the difference in pressure between two points within a system. They are widely employed in applications like flow measurement, filter monitoring, and level measurement, where pressure differences provide crucial data.

Submersible Pressure Transmitters: Built for measuring pressure in environments where the sensor must be submerged in a fluid, such as water level monitoring in tanks, reservoirs, or wells. These transmitters are rugged and waterproof, capable of withstanding harsh conditions.

High-Pressure Transmitters: These are used in industrial environments that deal with extreme pressures. They are designed for durability and precision, operating efficiently in systems like hydraulic machinery or gas storage facilities.

Digital Pressure Transmitters: These convert pressure readings into digital signals, providing higher precision and easy integration with automated control systems. They often feature advanced capabilities such as temperature compensation and enhanced diagnostics, making them suitable for applications demanding high accuracy.

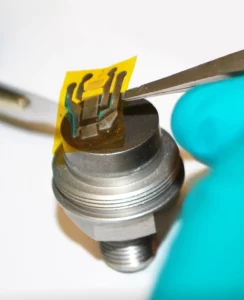

Silicon-on-Sapphire Sensor Technology

An important advancement in pressure transmitter technology is the use of Silicon-on-Sapphire (SoS) sensors. This technology combines the robustness of sapphire with the sensitivity of silicon, resulting in highly accurate and durable sensors. SoS sensors are especially valued in applications requiring high precision, resistance to extreme temperatures, and long-term stability. They are particularly beneficial in harsh environments, such as those found in the aerospace, oil and gas, and chemical industries.

Applications

Pressure transmitters are crucial across a wide range of applications, including:

- Monitoring pipeline pressure

- Wellhead pressure measurement

- Gas compressor systems

- Chemical Processing

Fluid level measurement in tanks

- HVAC Systems

- Air handling unit pressure monitoring

- Boiler pressure control

- Chiller system management

- Water and Wastewater Management

Water level monitoring in reservoirs and tanks

- Pump control and monitoring

- Sewer and drainage system pressure monitoring

- Manufacturing and Industrial Automation

Hydraulic system pressure monitoring

- Pneumatic system control

- Process control in production lines

- Cabin pressure control

- Engine pressure monitoring

- Environmental control systems

- Automotive Industry

- Fuel system pressure monitoring

- Brake system pressure measurement

- Engine performance optimisation

- Power Generation

Steam pressure monitoring in boilers

- Gas turbine pressure control

- Cooling system management

- Hydrogen Applications

- Hydrogen fuel cell pressure monitoring

- Hydrogen storage system pressure control

- Hydrogen refuelling station pressure management.

Food and Beverage Industry

- Pressure monitoring in pasteurisation processes

- Beverage carbonation level control

- Fluid transfer system pressure management

Choosing the Right Pressure Transmitter

Selecting the appropriate pressure transmitter depends on the specific operational needs, environmental conditions, and required accuracy. By providing reliable pressure data, these devices play a key role in ensuring the safe and efficient operation of various systems across multiple industries.

How Pressure Transmitters Work

How Pressure Transmitters Work

Oil and Gas Industry

Oil and Gas Industry