But what does SOS Technology Do for ESI?

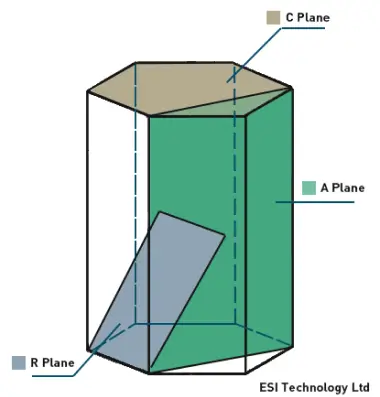

An SOS structure is essentially a semi-conductive surface. It provides the base for circuit and sensor manufacturing that is durable, resistant to heat and radiation, and performs consistently under varying levels of stress.

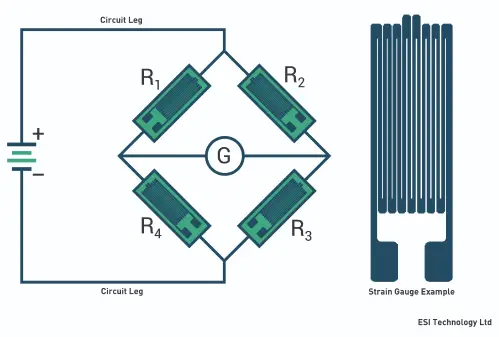

A Wheatstone bridge is formed in the Silicon during the manufacturing process of SOS sensors. This is a circuit used to measure electrical resistance between the two “legs” of the circuit.