SILICON-ON-SAPPHIRE (SOS) PRESSURE SENSORS

Why it is the superior choice for pressure sensing?

The ESI Unit converter allows you to quickly and easily access a conversion tool to work out your preferred unit of pressure measurement wherever you may be. Whether out on-site or in the office.

The ESI-USB© software allows you to connect your ESI transducer to your laptop or PC and be up and running monitoring pressure data within ten minutes. The software auto-updates and is compatible with Windows 8, 10 & 11.

Why it is the superior choice for pressure sensing?

Silicon-on-Sapphire (SoS) pressure sensor technology is an innovative and robust approach that combines the mechanical strength and high-temperature stability of sapphire with the advanced electronics of silicon.

As industries push for more reliable and precise pressure measurement under extreme conditions, SoS technology has emerged as a superior choice over traditional pressure sensors.

This white paper examines the benefits of Silicon-on-Sapphire pressure sensor technology, its applications, and the reasons why it outperforms other technologies in terms of durability, accuracy, temperature resilience, and miniaturisation potential.

Pressure sensing is critical in industries such as aerospace, automotive, hydrogen, oil and gas, medical, and industrial automation. As these sectors demand more from their sensors, particularly in extreme environmental conditions, traditional technologies like piezoresistive and strain-gauge-based sensors face limitations.

Silicon-on-Sapphire pressure sensors offer a significant advantage by leveraging the high purity and chemical inertness of sapphire substrates, allowing for sensors that are more stable and accurate under high-pressure and high-temperature conditions.

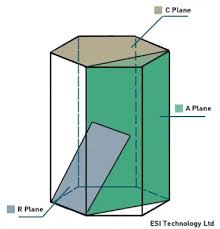

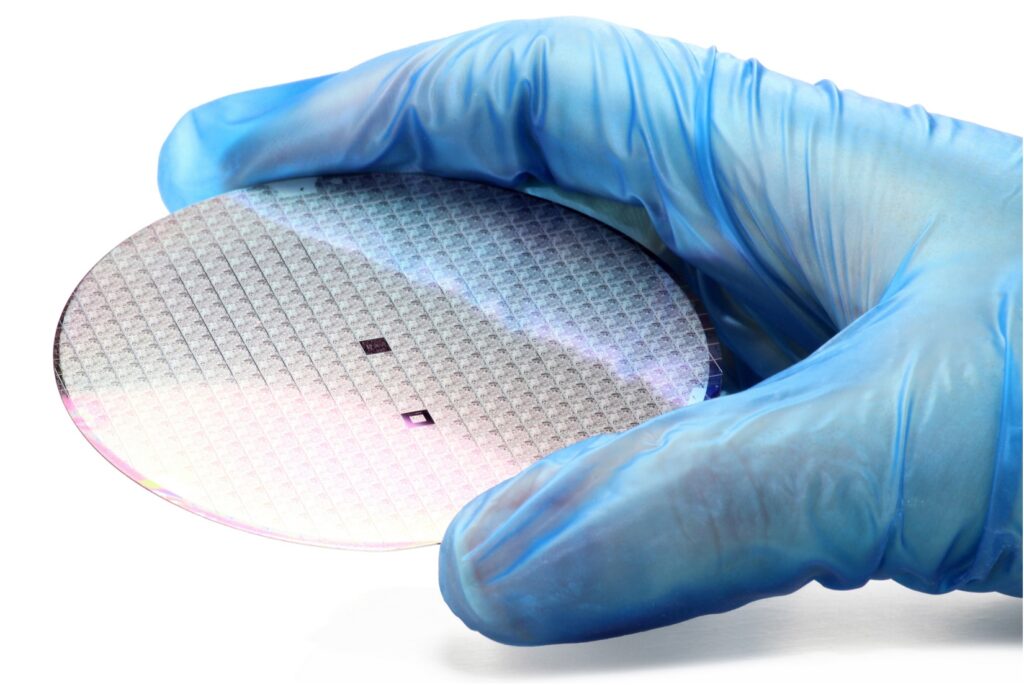

Silicon-on-Sapphire (SoS) technology involves growing a thin layer of silicon on a sapphire (aluminium oxide) substrate. Sapphire is an insulating and highly durable material with excellent thermal and mechanical properties. The crystalline structure of sapphire matches well with silicon, enabling silicon circuits to be fabricated directly onto the sapphire surface. This arrangement provides unique benefits in terms of durability, temperature stability, and miniaturization, making it highly suitable for creating reliable pressure sensors for harsh environments.

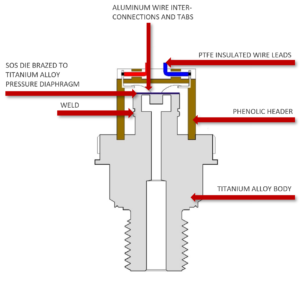

The pressure-sensing element is created by etching a strain gauge pattern into the doped silicon layer. The sapphire substrate provides excellent electrical isolation for the strain gauges due to its superior insulating properties. The high-temperature tolerance, chemical inertness, and minimal hysteresis of SoS technology makes it ideal for use in pressure sensors, ensuring reliable and accurate performance under demanding conditions.

3.1 High-Temperature Resilience

One of the most significant benefits of SoS technology is its ability to withstand extreme temperatures. Traditional silicon-based sensors degrade or fail when exposed to high temperatures due to the breakdown of silicon components and associated circuitry. Sapphire, however, can withstand temperatures up to 2,000°C, enabling SoS sensors to operate effectively in environments up to 300°C or higher without degradation. This makes them ideal for aerospace, automotive, and industrial applications where temperatures often exceed the capabilities of conventional sensors.

3.2 Mechanical Durability

3.3 High Precision and Accuracy

The insulating properties of sapphire minimise signal interference, resulting in highly accurate and precise measurements. In traditional silicon-based sensors, the signal noise introduced by temperature fluctuations and other environmental factors can degrade performance. SoS sensors, however, maintain high accuracy across a broad temperature range. Additionally, the silicon layer on sapphire allows for a highly sensitive and stable piezoresistive effect, which results in superior sensitivity and reduced drift over time.

3.4 Reduced Power Consumption

Silicon-on-Sapphire technology is well-suited for low-power applications due to the insulative properties of sapphire, which reduces parasitic capacitance and leakage currents. This reduced power consumption is advantageous in battery-operated or remote applications where energy efficiency is paramount. Other pressure sensing technologies may suffer from increased power requirements due to the need for temperature compensation or signal conditioning, which is less pronounced in SoS-based devices.

3.5 Miniaturisation and Integration Potential

Due to the compatibility of sapphire with silicon circuitry, SoS sensors allow for significant miniaturisation and integration of electronic components. This miniaturisation is critical for applications requiring compact, lightweight sensors, such as in aerospace and wearable medical devices. Moreover, SoS technology facilitates the integration of advanced functionalities, such as wireless communication or data processing directly on the sensor chip, without compromising durability or performance.

4.1 Piezoresistive Sensors

Piezoresistive sensors use the piezoresistive effect in silicon to measure pressure. While widely used, they are sensitive to temperature variations, which can introduce errors. They often require additional temperature compensation circuitry, which increases power consumption and limits performance at high temperatures. SoS sensors, by contrast, are inherently stable across temperature ranges, providing a significant advantage in extreme environments.

4.2 Strain Gauge Sensors

Strain gauge sensors rely on resistive elements to measure strain, which correlates to pressure. These sensors are generally less sensitive and have a slower response time compared to SoS sensors. They are also less durable due to the materials involved, making them less suitable for high-temperature or high-pressure environments where SoS sensors excel.

5.1 Aerospace and Defence

The aerospace industry demands sensors that can operate reliably under extreme temperature and pressure variations, such as those encountered in engines or at high altitudes. SoS sensors are ideally suited for these conditions, where other sensor technologies may fail.

5.2 Automotive Industry

Automotive applications, particularly in engine monitoring and exhaust systems, require sensors that withstand high temperatures and provide accurate readings over extended periods. SoS sensors enable better fuel efficiency and emissions control by providing precise, real-time data even in high-temperature engine environments.

5.3 Oil and Gas

In oil and gas exploration, sensors are frequently exposed to corrosive and high-pressure conditions. SoS sensors’ durability and temperature stability allow for more reliable monitoring of pressure in drilling and extraction equipment.

Industrial environments often involve temperature fluctuations, high pressure, and chemical exposure. SoS pressure sensors, with their robustness and accuracy, enhance process control and safety in manufacturing, chemical processing, and power generation.

5.5 Hydrogen

In Hydrogen applications, environments frequently experience extreme conditions such as temperature variations, high pressures, and exposure to harsh chemicals. Silicon-on-Sapphire (SoS) pressure sensors excel in these settings due to their unparalleled durability and precision. Their resilience ensures reliable performance, making them ideal for applications like manufacturing, chemical processing, and power generation, where process control and safety are paramount.

5.6 Hazardous Areas

Silicon-on-Sapphire (SoS) pressure sensors are superior in hazardous area applications due to their exceptional durability, chemical resistance, and ability to operate reliably in extreme environments. Unlike conventional pressure sensors, SoS technology combines the hardness of sapphire with the stability of silicon, making them highly resistant to corrosion, high temperatures, and mechanical stress. This ensures accurate performance and long-term reliability in hazardous areas, where safety and precision are critical, outperforming alternative sensor technologies.

5.7 Marine

Silicon-on-Sapphire (SoS) pressure sensors are ideal for marine applications due to their unmatched resistance to harsh environmental conditions such as saltwater corrosion, extreme pressures, and wide temperature fluctuations. Unlike traditional pressure sensors, the sapphire substrate in SoS sensors offers exceptional durability and chemical stability, ensuring accurate and reliable performance in the demanding marine environment. This makes them the superior choice for applications like underwater exploration, ship systems, and offshore oil and gas operations, where reliability and longevity are critical.

5.8 OEM

For OEM applications, where design flexibility is essential, pressure sensors built with Silicon-on-Sapphire (SoS) technology stand out due to their ability to be easily customised for specific requirements. Their compact design, combined with high accuracy and robust performance, ensures seamless integration into a wide range of systems, even in demanding conditions. Unlike other sensor technologies, SoS sensors deliver exceptional reliability under extreme temperatures and pressures, making them the ideal solution for OEM needs that demand precision and adaptability.

While SoS pressure sensors offer numerous benefits, they face challenges in terms of production costs and process complexity. The synthesis of high-quality sapphire substrates and integration with silicon can be more expensive than other sensor technologies. However, as demand for durable, high-performance sensors grows, economies of scale and advancements in fabrication techniques are likely to drive costs down.

Future developments may focus on further miniaturisation, integration of additional functionalities (e.g., wireless communication), and expansion into even broader applications. With the advent of the Internet of Things (IoT), SoS sensors are well-positioned to support increasingly complex data-driven environments.

Silicon-on-Sapphire pressure sensor technology represents a significant advancement over traditional pressure sensing technologies, offering superior performance in terms of temperature resilience, mechanical durability, accuracy, power efficiency, and miniaturization potential. As industries demand more robust and accurate pressure sensors for use in extreme conditions, SoS sensors are emerging as a preferred choice. Their advantages make them ideal for a wide range of applications, including aerospace, automotive, oil and gas, and industrial automation, where reliability and precision are critical.

By overcoming the limitations of conventional pressure sensors, Silicon-on-Sapphire technology is not only enhancing current industrial practices but also paving the way for new applications and advancements in pressure sensing.